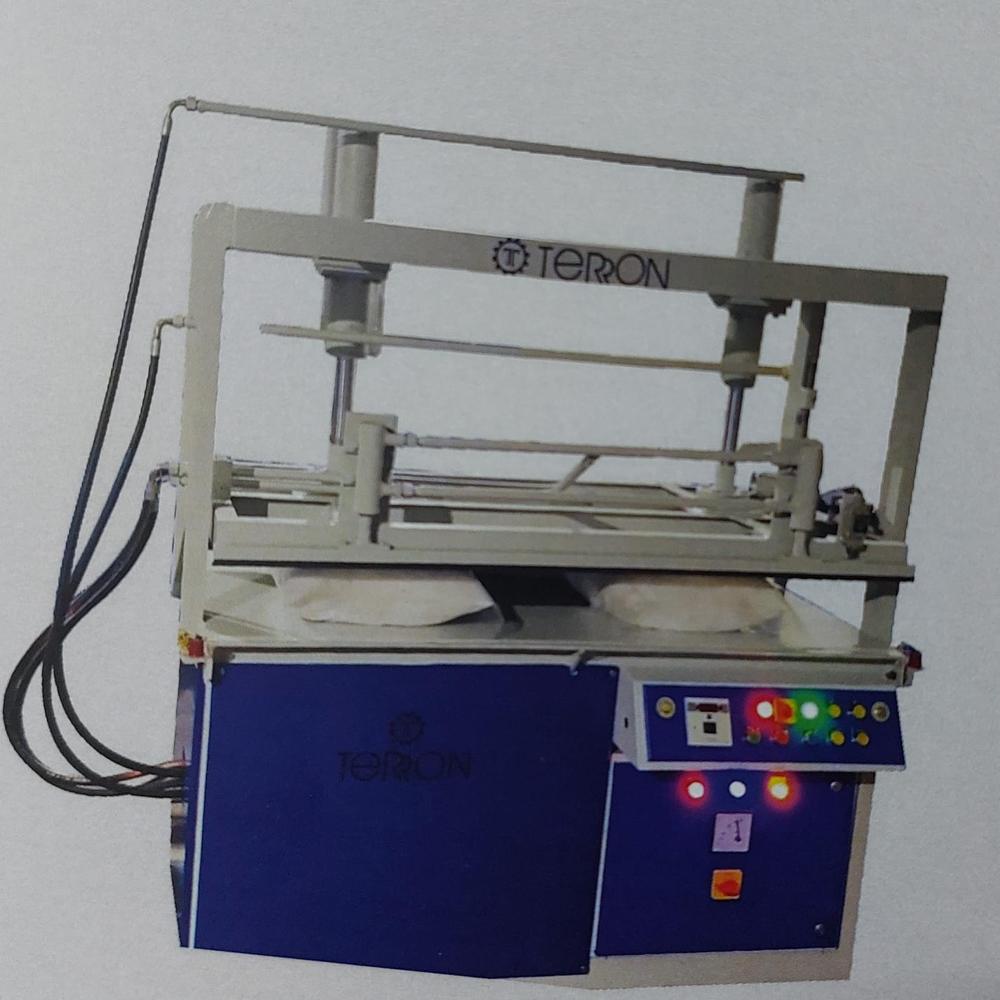

Pillow/ Cushion Compression Packing Machine

Pillow/ Cushion Compression Packing Machine Specification

- Features

- Good Quality

- Usage

- Industrial

- Power Supply

- Electric

- Material

- MS

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Hydraulic

- Voltage

- 110-215 Volt (v)

- Warranty

- 1 Year

Pillow/ Cushion Compression Packing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Telegraphic Transfer (T/T)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 10-15 Days

- Certifications

- ISO,CE

About Pillow/ Cushion Compression Packing Machine

* Technical Specifications :- Output 1 Pillow 15 Seconds* Electrical Specificatios :- Power 1kw .

* Phase :- single

* Machine Weight :- 100kg

* Machine Size :- 21x30 inch

* warranty :- 1 Year Manufacturing Warranty

* Usage :- Pillow , Cushion , Ect

. in Built Operating Panel

. Air Compressor

Streamlined Compression for Industrial Needs

Designed for industrial-scale operations, this semi-automatic pillow and cushion compression packing machine simplifies packaging processes. The hydraulic drive ensures uniform compression, while the Human Machine Interface offers straightforward control with minimal training required.

Durability and Ease of Use

Manufactured from high-quality MS, this machine promises longevity in heavy use environments. Its semi-automatic design and non-computerized control make it a practical solution for businesses needing reliable yet uncomplicated machinery for everyday operations.

FAQs of Pillow/ Cushion Compression Packing Machine:

Q: How does the semi-automatic compression packing machine operate?

A: The semi-automatic machine uses hydraulic power to compress pillows or cushions before packing. Operators use the Human Machine Interface to control and monitor the process, ensuring uniform compression and efficient packaging.Q: What are the main benefits of using this compression packing machine?

A: It offers space savings during storage and transportation by significantly reducing the volume of pillows and cushions. The machine also improves packaging consistency, minimizing labor costs and protecting product quality during handling.Q: Where is this compression packing machine manufactured and supplied?

A: This machine is manufactured and supplied in India, meeting the specific requirements of local manufacturers and industrial users.Q: When should I use this compression packing machine in my operation?

A: The machine is ideal for use in industrial settings where large volumes of pillows or cushions need to be packed efficiently for storage or shipment, ensuring optimal utilization of space and protection against transit damage.Q: What materials and components are used in the machines construction?

A: Constructed from MS (mild steel), the packing machine is built for strength and durability. Its reliable hydraulic system and electric power operation ensure consistent performance in demanding environments.Q: What is the process for maintaining this packing machine?

A: Regular cleaning of the moving parts, periodic inspection of hydraulic systems, and prompt attention to any unusual noises or drops in performance ensure long-term efficiency. Maintenance is straightforward due to the machines non-computerized design.Q: Is any specialized training required to operate the machine?

A: Thanks to its Human Machine Interface and semi-automatic configuration, minimal training is needed. Basic operational and safety guidance is typically sufficient to use the machine effectively.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Compression Packing Machine Category

Dog Bed Compression Packing Machine in Hydraulic

Price 215000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Usage : Industrial

Automatic Grade : SemiAutomatic

Warranty : 1 Year

Quilt Compression Packing Machine

Price 215000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Usage : Industrial

Automatic Grade : SemiAutomatic

Warranty : 1 Year

Cushion Compression Packing Machine in Pneumatic

Price 150000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Usage : Industrial

Automatic Grade : SemiAutomatic

Warranty : 1 Year

Automatic Pneumactic Pillow Compression Packing Machine

Price 150000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Usage : Industrial

Automatic Grade : SemiAutomatic

Warranty : 1 Year

Send Inquiry

Send Inquiry